How High Mix Low Volume Outsource Makes High-Profitability Sense

A Lean Approach to Low-Volume Production

- Manufacturers can enhance management of HMLV production by engaging LEAN suppliers.

- Manufacturers need a more focused, creative and flexible solution for finding HMLV supplier partners.

- Outsourcing the entire HMLV function frees managers to do what they do best – manage high-volume business.

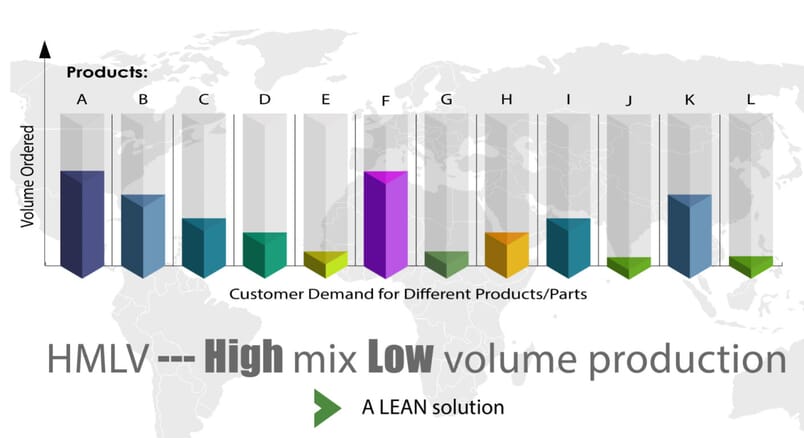

There are three reasons why high-mix, low-volume (HMLV) products are proliferating:

- A growing trend toward corporate mergers and acquisitions, which compounds product offerings while consolidating production management;

- Customer demands for more choices and more product variations, even to the point of customization;

- The fact that today’s manufactured goods are better made and are performing longer, requiring manufacturers to continue to produce and offer replacement parts for obsolete models that are still in service.

One of the ways that manufacturers can enhance their management of an HMLV basket of components is to engage suppliers that implement LEAN methodologies in their manufacturing and supply chain processes.

Just as is true for so many aspects of HMLV production management, finding suppliers who are willing to take on low-volume runs and already subscribe to LEAN principles is easier said than done.

Many of the smaller suppliers that are inclined to take on high-variation, low-volume business are less inclined to commit to investing in LEAN methodologies. LEAN is a discipline that requires significant process and cultural changes as well as unaccustomed patience on the part of executive management.

It may be a challenge to find smaller, nimble suppliers who are willing to take on HMLV assignments and are also LEAN qualified. But the benefits of working with a LEAN practitioner make such a search worth the effort.

When LEAN drives the suppliers’ production and supply chain practices, end customers have a better assurance that the HMLV components they receive will be free of the kind of production and delivery compromises that are too often typical of suppliers who do not follow LEAN principles. In addition, by relying on HMLV component suppliers with a track record of long-term effectiveness, manufacturing and supply chain managers increase the likelihood that the components they need will be made to the quality desired and delivered as promised.

LEAN compliance is only one of the characteristics of dependable HMLV sources. Here are the top five considerations in selecting an HMLV supplier.

- Rely on suppliers who have already established a record of success with HMLV production. Building an effective HMLV supply chain requires finding those suppliers who are interested in low-volume production and have the experience and technical setups to run smaller batches, while executing changeovers efficiently. It’s possible to assemble a mix of suppliers that would be delighted to cater to the demanding requirements of producing HMLV components and still be profitable doing so … if you know where to look.

- Be willing to offer HMLV contracts as part of a mix. Many small suppliers are willing to take on the production of HMLV components with one important condition: they also want to be promised higher volume business to complement the HMLV work. Supply chain managers must be willing to negotiate a strategy where HMLV components are produced as part of a mix with steady-running parts – and without compromising on quality or delivery. That mindset sets the stage for a win-win relationship between the HMLV supplier and the end customer.

- Consider vertically integrated suppliers. Suppliers with in-house capabilities for the fabrication of tooling are often best equipped to handle HMLV component production. Their proven ability to make gages, tooling and fixtures quickly and at a lower cost makes them more likely to control their costs and deliver HMLV components at attractive prices.

- Re-think supply chain planning. HMLV components are notoriously difficult to forecast and present difficult and special challenges in terms of packaging efficiency and shipping methods. Standard analytical S&OP supply chain methods and processes do not work for HMLV components, which require flexible and responsive supply chain practices based on prompt goods consolidation.

- Re-think what is meant by “standard processes.” What is “standard” in high-volume production often becomes a productivity trap for HMLV products. Experience has taught us to rely exclusively on HMLV suppliers that incorporate LEAN methodologies, including advanced product quality planning (APQP) and other continuous improvement and project management tools.

Since HMLV offerings will not be going away any time soon, manufacturers need to re-examine their approach to selecting and managing HMLV suppliers. They need a more focused, creative and flexible solution for discovering willing HMLV supplier partners who know how to ensure a smooth and reliable supply of components.

How does a manufacturer find those HMLV suppliers, and then manage them effectively, when there isn’t enough time to do either? The answer: Turn to someone who already does.

Companies understand the benefits of outsourcing non-core business functions and moving production off-shore to maximize quality and cost savings. Outsourcing management of HMLV suppliers offers comparable benefits:

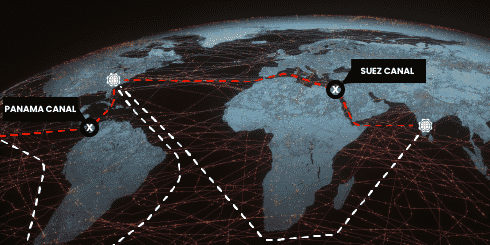

- It expands the available pool of qualified, willing HMLV suppliers by adding overseas suppliers that are LEAN-compliant and experienced in high-variation production.

- It allows production and supply chain managers to focus on core, high-volume product lines.

Regarding the challenges of low-volume production on a global scale, manufacturers and supply chain managers will have to think differently than they have in the past. In today’s complex and competitive business environment, they simply cannot afford to rely on high-volume thinking when looking for economical expediencies in low-volume supply chain management.

Outsourcing the entire HMLV function can free manufacturing and supply chain managers to do what they do best – manage high-volume business – while improving the reliability and productivity of their “under the radar” HMLV supply chains.