Customer Resiliency

-

In a growing fractured world, supply chain teams need to build resiliency. Sourcing organizations must offer business options with suppliers while meeting cost, quality, and delivery metrics. It’s a tough job!

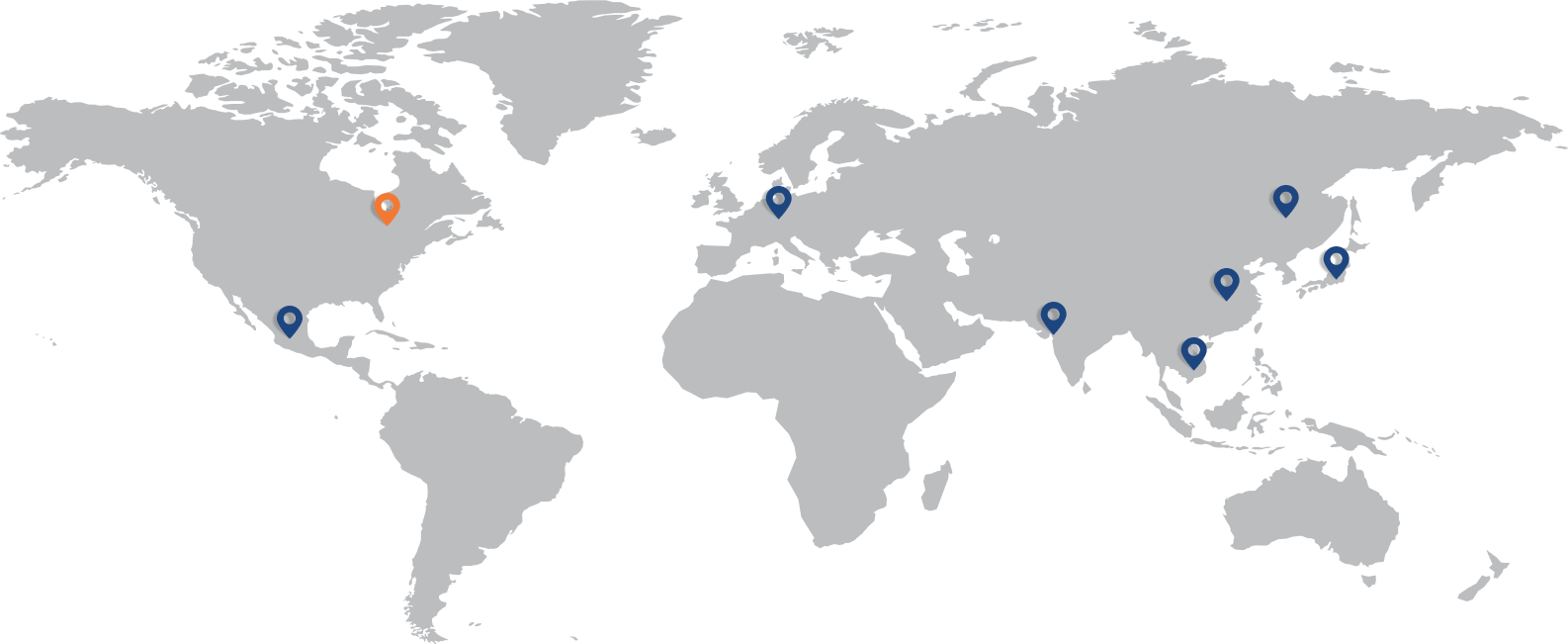

We have maintained best-in-class delivery metrics through the Covid, Tariffs, and Shipping container crisis. This includes shipping from India, China, Vietnam and within US and Mexico. Our warehouses are close to customers in Mexico, US and Poland

As global sourcing and supply chain experts, we have established ourselves as the go-to partner for many Fortune 500 industrial companies looking for the right balance of lead times and cost. We have spent years developing our worldwide suppliers to give customers exactly what they look for: best-in-class manufacturing suppliers.

Learn More -

It’s one thing to find capable suppliers who are motivated and aligned to meet tough standards of delivery, lead times, and cost. But it’s yet another to get those quality goods ready for assembly lines at our OEM customers in Europe, the US, and Mexico!

We do this by onboarding our robust suppliers on the Metrics Portal to communicate and change orders, dates, and lead times. We also develop two partners for each major route around the world, preferring the flexibility and agility of container traffic over cost.

We then break down our entire lead time into five phases, including supplier manufacturing time, In-country transportation, ocean transportation, trucking, and last-mile coverage to our warehouse. We further provide our planners with visibility into our system for each shipment and its location at all times to help them optimize lead times and inventory levels.

Learn More -

Most customers would like to have their goods produced within 100 miles of their assembly plants, but in this global manufacturing landscape, that is merely a dream.

Nearshoring is expensive. Even if companies can convince some suppliers to build close-by, it is difficult to find a labor pool to manufacture and an engineering pool to develop and set up.

Manufacturing becomes even more expensive as customers expect mass customization, proliferating the SKUs and needing fast change-overs of tooling and set-ups.

Transportation from Mexico to the US has become as expensive as the cost of a container from Shanghai to LA. Nearshoring advantages tend to dwindle when manufacturing lead times are longer and no shipping cost advantage exists.

Sourcing executives have to weigh the difficult choices between nearshoring and global sourcing. MES has no bias toward either. We have committed manufacturing partners in Mexico, as well as our own warehousing, light manufacturing and assembly, and CNC machining in the US and Mexico. We are all-in on these solutions when optimal cost is achieved for customers.

Learn More

In a growing fractured world, supply chain teams need to build resiliency. Sourcing organizations must offer business options with suppliers while meeting cost, quality, and delivery metrics. It’s a tough job!

We have maintained best-in-class delivery metrics through the Covid, Tariffs, and Shipping container crisis. This includes shipping from India, China, Vietnam and within US and Mexico. Our warehouses are close to customers in Mexico, US and Poland

As global sourcing and supply chain experts, we have established ourselves as the go-to partner for many Fortune 500 industrial companies looking for the right balance of lead times and cost. We have spent years developing our worldwide suppliers to give customers exactly what they look for: best-in-class manufacturing suppliers.

Learn More

It’s one thing to find capable suppliers who are motivated and aligned to meet tough standards of delivery, lead times, and cost. But it’s yet another to get those quality goods ready for assembly lines at our OEM customers in Europe, the US, and Mexico!

We do this by onboarding our robust suppliers on the Metrics Portal to communicate and change orders, dates, and lead times. We also develop two partners for each major route around the world, preferring the flexibility and agility of container traffic over cost.

We then break down our entire lead time into five phases, including supplier manufacturing time, In-country transportation, ocean transportation, trucking, and last-mile coverage to our warehouse. We further provide our planners with visibility into our system for each shipment and its location at all times to help them optimize lead times and inventory levels.

Learn More

Most customers would like to have their goods produced within 100 miles of their assembly plants, but in this global manufacturing landscape, that is merely a dream.

Nearshoring is expensive. Even if companies can convince some suppliers to build close-by, it is difficult to find a labor pool to manufacture and an engineering pool to develop and set up.

Manufacturing becomes even more expensive as customers expect mass customization, proliferating the SKUs and needing fast change-overs of tooling and set-ups.

Transportation from Mexico to the US has become as expensive as the cost of a container from Shanghai to LA. Nearshoring advantages tend to dwindle when manufacturing lead times are longer and no shipping cost advantage exists.

Sourcing executives have to weigh the difficult choices between nearshoring and global sourcing. MES has no bias toward either. We have committed manufacturing partners in Mexico, as well as our own warehousing, light manufacturing and assembly, and CNC machining in the US and Mexico. We are all-in on these solutions when optimal cost is achieved for customers.

Learn More