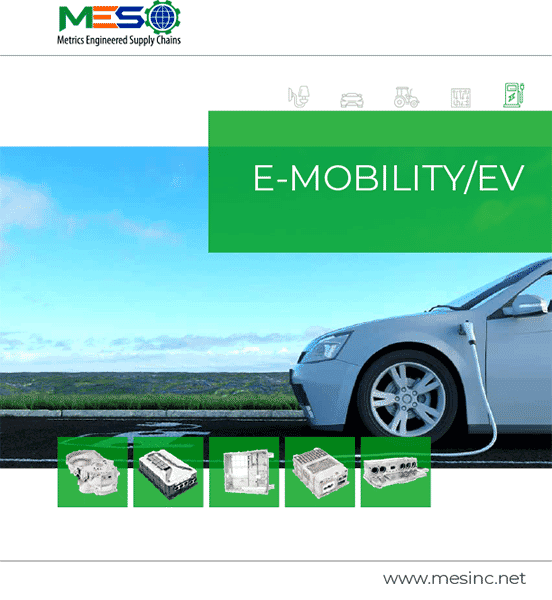

E-Mobility

MES Electric Vehicle Solutions

- Partner with many Tier I manufacturing customers & provide castings, forgings, machinings, stampings for electric vehicles

- Provide best-in-class engineering & global supply chain solutions

- Deliver cost-effective product & tooling solutions

- Superior product & tooling lead times

- Offer many value-added services including supply chain, engineering design & troubleshooting, quality management, warehousing, inventory management & more

The current generation of electric vehicles is designed to address the sensibilities of the climate-conscious consumer, reducing the need for oil consumption, lowering emissions and going farther on new battery cell technologies, all without compromising on the speed, torque, and efficiency demanded by the car-buying public.

Win the race for electric vehicle components

Your job: Accelerating production of clean, fuel-efficient vehicles to electric and hybrid drivers.

Our job: Speeding manufactured e-mobility components and assemblies to you.

TIER 1 AUTOMOTIVE SUPPLIER

Next-generation EV parts

You’re in the middle of an automotive revolution. Let MES keep you in the fast lane with manufactured parts, components, and assemblies, quality checked by our high-tech, on-staff project engineers.

EXPEDITED ELECTRIC VEHICLE DEVELOPMENT

Ramp up, scale down

Right now, unpredictability is a given for electric vehicle development. Which is even more reason to always be at the ready. At MES, readiness is the only way we know how to do business. It’s built into our rapid-response processes. It’s inherent in our ISO certified global supplier network.

GIVE STAKEHOLDERS WHAT THEY WANT

60% lower costs and faster lead times

It costs money to shift toward or expand electric vehicle production. When you partner with MES, you get a partner that knows how to maximize your investment and mitigate your risks. In addition to supplying mechanical and metal components for EV vehicles, MES can drastically cut tooling costs while dramatically improving lead times.

Get Started

Want to know how to get superior EV castings, forgings, machinings, and stampings delivered on time and within budget?

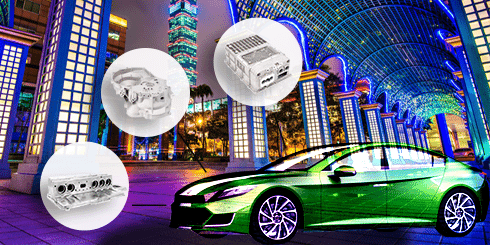

MES supplies several mechanical components for electric vehicles, including inverters, power electronic controllers, stators, rotors, motor housings, and a range of chassis components. We assist in designing low-weight metal components made out of aluminum, magnesium, and zinc to help with fuel efficiency and performance desired out of EV vehicle components.

Adaptable for engineering changes and optimization all the way into production.

Electric vehicle efficiency, technology and range will continue to evolve and change rapidly with battery, motor and power management technology. Supporting mechanical components will also need to keep up with these evolving changes. MES has a rapid response engineering supplier and engineering change management process (Four gates MESHAPQP to limit inventory in the system and ensure thorough changes to upgrade components within weeks and months instead of years.

MES Manufacturing Capabilities

Die Casting

- Aluminum

- Magnesium

- Zinc

- Copper

Sand Casting

- Ductile Iron

- Grey Iron

- Carbon Steel

- Stainless Steel

- Brass

- Bronze

- Copper

Investment Casting

- Carbon Steel

- Stainless Steel

- Nickel

- Ductile Iron

- Grey Iron

Forging

- Aluminum

- Brass

- Copper

- Titanium

- Zinc

- Carbon Steel

- Stainless Steel

Extrusion

- Aluminum

- Plastics

- Copper

- Rubber

CNC Machining

- Aluminum

- Brass

- Copper

- Titanium

- Zinc

- Carbon Steel

- Ductile Iron

- Grey Iron

- Stainless Steel

Scalable to quick ramp-ups

Electric vehicle ramp-up schedules and end volumes will depend upon adoption in the market. Many of the EV’s designed with high volumes may end up with lower than expected volumes, and in certain cases, the opposite would be true. MES has a supplier management process including dual country, backup sourcing, tooling sourcing to ramp-up volumes in different parts of the world using standardized tooling, process, and packaging methods.

Tooling Cost – 40% of domestic suppliers

Electric vehicle manufacturers face heavy scrutiny by outside stakeholders for capital and financial burn rates. MES can lower the development costs by almost 60-70% over domestic manufacturers in Europe, US and Mexico.

Lead times to support your aggressive and unrealistic timeframes! – 8 weeks for all level 3 PPAP’s.

Electric vehicle development schedules will continue to be unrealistically short, expecting Level 5 PPAP’s within weeks instead of months which domestic sourcing companies can meet. MES routinely develops a variety of castings, forgings, extrusions, and machined components within 6-8 weeks for Initial PPAP’s and then ramps up production using our “Safe-Launch” process.

E-mobility is a heavy user of lightweight engineered aluminum die castings which are meticulously machined to high tolerances and complex heat sink and thermal protection features. Our performance without compromise is reflected in every casting component produced for the e-mobility industry. It starts with carefully selecting the global suppliers who can pass our stringent standards, who are ISO and IATF certified, and who have proven – repeatedly – that they can deliver cost-effective, timely, quality parts.

When the tolerance for anything short of perfection has to be zero, MES is ready to take on the challenge. We’re here to help, having already supplied thousands of power converter housings, interior housings, battery trays, and more to OEM’s around the globe.

EV Virtual Showroom

Checkout our EV Virtual Showroom