Developing Critical Sand Blasting Process and Supplier in Mexico for Demanding Aesthetics. – MES

Executive Summary

Reverse engineering a product can be a formidable task, especially when the underlying process remains shrouded in ambiguity. But what if the product’s specification itself is equally enigmatic? This dual challenge often confronts engineers and manufacturers as they strive to unravel the intricacies of existing designs.

Consider die-casting—a common manufacturing technique. To achieve the desired finish, most die-casting parts undergo sandblasting. However, this finish is not a straightforward, objective measurement. Instead, it relies on subjective judgment and qualitative criteria. Picture a scenario where the specific engineering or marketing team must first approve the finish. Subsequently, the manufacturer produces initial parts, which serve as samples awaiting buyer approval. Finally, the manufacturer must maintain consistent production quality across thousands of parts, ensuring they match the exact original finish.

Yet, achieving a finish that rivals that of competitors becomes akin to participating in a Keynesian Beauty Contest, a theory derived from the world of behavioral finance. Here’s the analogy: Just as we try to predict what our friends find “beautiful” in their next partner; we often misjudge their preferences. Similarly, attempting to anticipate what others value—whether in aesthetics, functionality, or quality—can lead us astray.

MES Inc., known for its resilience and adaptability, encountered a challenge last October. Despite proactive planning, disruptions arose, demanding maturity and resourcefulness. Specifically, the company faced hurdles related to a sandblasting order requested by a loyal, long-standing customer. Here is an overview of this case.

The Overview

One of our energy-based customers came to us with a part that had already been sand blasted by a previous supplier and asked us to match the manufacturing of the piece. When MES’s APQP management team asked for the process of the previously employed supplier the buyer explained that they could not share the process due to proprietary regulations. Drawing specifications did not mention specific finish so initial discussion with customer was contentious but at the end of the day, our team had to guess our customer’s preference. Hence, the first of many challenges in this case is presented as MES is attempting to reach a standard for a finished product that we do not know how to achieve. Although a challenge was ahead of MES’s supply chain and sourcing departments, they did not waver in the decision to find a solution for their long-time customer. Our sourcing and quality management team immediately got to work on finding a supplier who could sandblast thousands of materials and requested samples. The samples arrived and were approved by the buyer, yet little did MES know that the next challenge was just around the corner.

The supplier was then tasked with manufacturing a small batch of the desired part for quality assurance purposes, but when it came time to present the smaller batch the supplier explained that they could not consistently provide the same quality across all parts as they were using a manual sand blaster and they were using a different type of sand than the kind they had used for the original samples.

TIMELINE:

MES has developed well over 1500 die castings with various finishes, achieved by different sand blasting, bead blasting and others. These finishes are achieved by using specific “media” of sand and stones and differing types of machines – manual, automated, including drum and various other equipment types.

When the initial supplier was not able to duplicate what the customer wanted, and when MES could not ascertain the process that was being used by the competitor, the sourcing and quality departments organized themselves into teams to review various processes, suppliers, and technologies. Here is a brief overview regarding the timeline of events for this project:

Thursday January 4, 2024: The new supplier started the first pallet with the new sand, and MES detected a slight difference from the original sample that was caused by the sand exposition time. They then worked with the buyer to discover that the best process to accomplish the desired finish was to increase the sand exposition time from 1.5 minutes to 3 minutes.

Monday January 8, 2024: MES confirmed with the buyer that they did not urgently need the parts to be delivered, but instead desired a tentative timeline of when they would be produced. MES’s team informed the buyer that they were working diligently to find a supplier that can produce acceptable parts consistently and would be in open communication with them regarding this process.

Tuesday January 9, 2024: MES approached seven different suppliers for quotes for the project.

Thursday January 25, 2024: By this point multiple suppliers’ samples have been analyzed and rejected for various reasons including color, size, and process. However, at this point MES has narrowed their search down for a supplier to three and sent samples off to the buyer for review. With great excitement, one of the three samples was accepted.

Friday February 2, 2024: The following message was received by MES’s team regarding the sample, “we had a conference with the owner of this product, they asked above all about the tone, it looks yellow, versus silver from the original sample.” They responded to this feedback by continuing to diligently work with the original seven suppliers to find one that could produce a product the buyer approved of.

Wednesday February 14, 2024: The buyer approves of a sample piece from a different supplier.

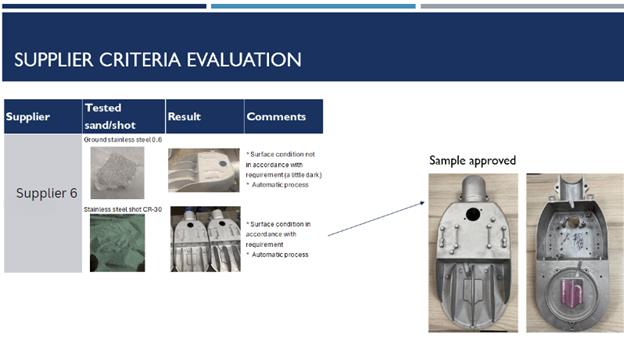

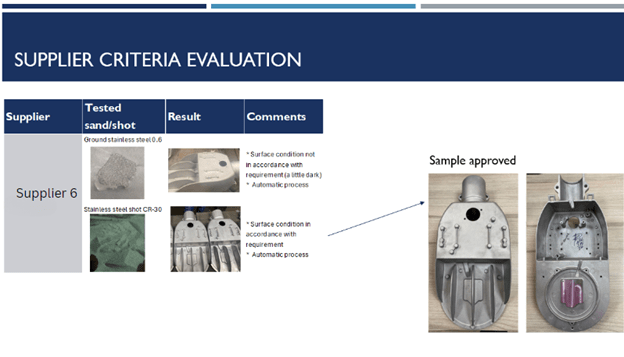

Friday February 23, 2024: MES’s team is notified that the supplier is having an issue with the shot blasting parts being darker than the approved samples. When MES notified the supplier, the supplier explained that they had various hypotheses for why the difference in color was present and that they planned to conduct tests to determine the cause of the issue.

Wednesday February 28, 2024: Supplier came back with an entirely different process to fix the issue regarding the variation in color. Nonetheless, the process is approved as it provides consistent manufactured parts.

Monday March 4, 2024:120 pieces are produced yet only 65 were identified as being acceptable to send to the buyer by an inspector. The other pieces were not consistent with the sample due to drip marks, masking residue, oil marks, and dark finishes. MES still sent the batch of 65 pieces to the buyer to confirm they are approved in terms of quality.

Monday March 11, 2024: The buyer approved the 65 pieces sent on March 4th. During the time between sending the pieces to the buyer and their approval response, our supplier was diligently working on updating the process to get parts produced in a consistent manner. It was on this day that our supplier was able to produce 120 pieces that were all 100% deemed acceptable to be shipped to the buyer.

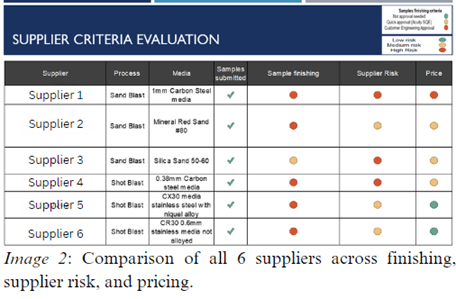

However, the real story here is not within the details of the timeline but in how we trialed various methods from 6 different suppliers to find the perfect sandblasting media.

Finding the Perfect Media

As previously stated, the MES team reached out to various suppliers to try and discover a method of sandblasting so we could achieve a particular standard finish of product for the buyer. We provided show samples and determined which trials to run to get the finish they desired.