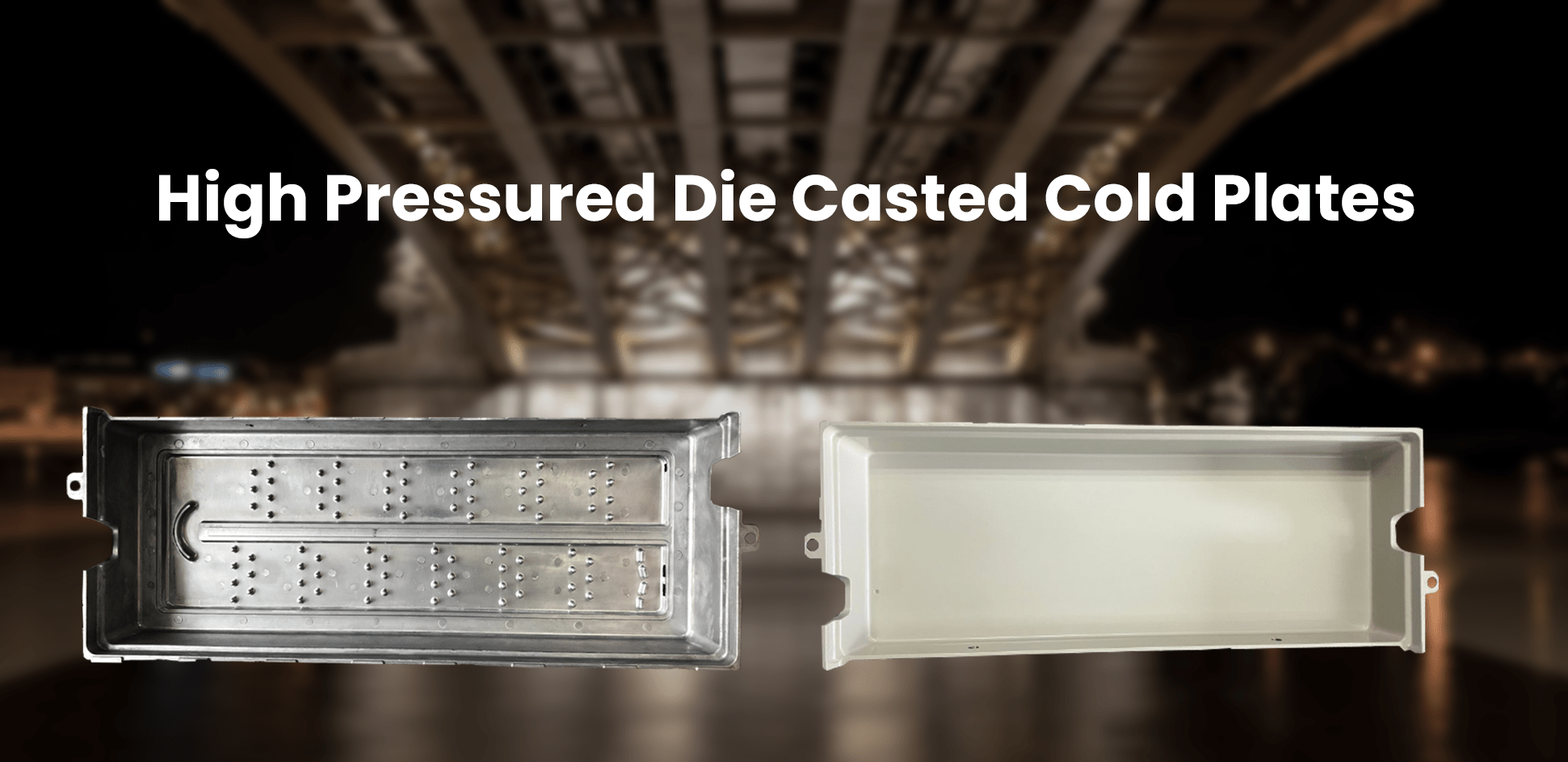

Vendor Selection

MES is an proven supplier in electric vehicle solutions (e-mobility), having supplied a wide variety of customers with EV housings, inverters, heat sinks, cold plates, battery trays. MES also is a veteran of EV market research, including partnering with The Ohio State University on a thermal characteristics program designed to support the development of high-performing components. So, although this particular startup had never worked with MES, they were acutely aware of MES’s track record of producing similar parts and providing proof supply chain solutions to ensure timely executions and delivery while being able to adjust at a moment’s notice and with an EV startup, that can be often.

But that was only the beginning …

Global Supply Network

“Integration and partnership are cornerstones for MES, but it’s even more critical in the EV industry with its ever-changing and continuously improving processes,” says Bhavin Shah, Director of Sourcing and Estimating for MES. “That’s why we involved sales, sourcing, and quality team members from both the U.S. and China. Together, we determined which suppliers have both the manufacturing capabilities this customer needed, as well as the communication skills and long-term commitment required for a project of this significance and magnitude.”

Origin-Country Sourcing and Supplier Expertise

MES began this engagement by evaluating the customer’s technical requirements based on the customer-supplied drawings and models. Then, the MES origin-country sourcing team assessed the short-listed suppliers chosen from MES’s vast global network before narrowing it down to find the most experienced supplier that’s required for the project, including advanced machining technologies such as Friction Stir Welding (FSW). Friction Stir Welding is a specialized process of joining two pieces much more efficiently than traditional welding techniques. Battery applications benefit from the process due to minimal distortion, lower cost, and watertight seals created to assist with heat transfer.

“We chose one of our suppliers in China specifically based on their expertise with FSW,” says Bhavin.“ They also excel in their ability to communicate on the technical front with both our team and the EV customer.”

Technical and Engineering Capabilities

MES then provided value-added engineering services, which is critical to successful new product launches. Based on a prudent DFM (design for manufacturability) review and resulting adjustments, MES demonstrated what was—and was not—feasible for the project. This enabled MES to develop a robust part set while also virtually eliminating the risk of manufacturing and quality issues.

“The exchange between the customer, the supplier, and MES was educational all the way around,” says Austin. “The customer doesn’t have a team of 100 engineers (yet), but, in combination with MES and its suppliers, it had the equivalent. Our collaboration was, honestly, very natural and easy. Our team would go through the proposed project plan and designs and collaborate transparently. We would put forth the time and effort required to meet the requirements, so in a matter of months, we landed on a final design. Now, MES has earned a tooling purchase order, the first-year Beta build of parts, and big plans to help our customers succeed. Collaboration amongst MES locally and in-country, the end-manufacturer, and our customer-led to extreme efficiencies at such an early and fragile stage.”