Inverter Research: Using a Test Rig to Improve EV Batteries

What do a group of student researchers, thermal response, and MES have in common? They’re all part of a relatively new research project focused on the study of thermal management and predictive modeling to develop better EV batteries for the burgeoning e-Mobility market.

This collaboration between MES and researchers at The Ohio State University is well underway, with lots of progress being made in understanding how to create an effective thermal design; something that, of course, automotive OEMs are in need of.

Here’s a look at the latest in this joint research project; this one involving the development and validation of a test rig that can simulate real-world conditions and enable predictive modeling.

How a Test Rig Can Further Next-Gen Inverter Designs

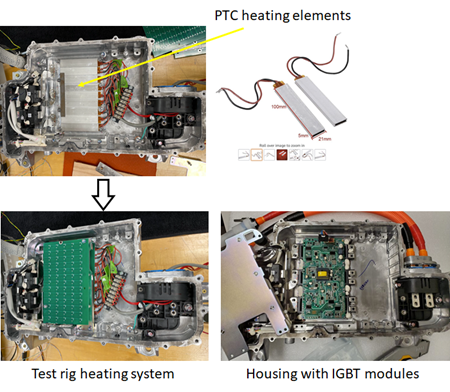

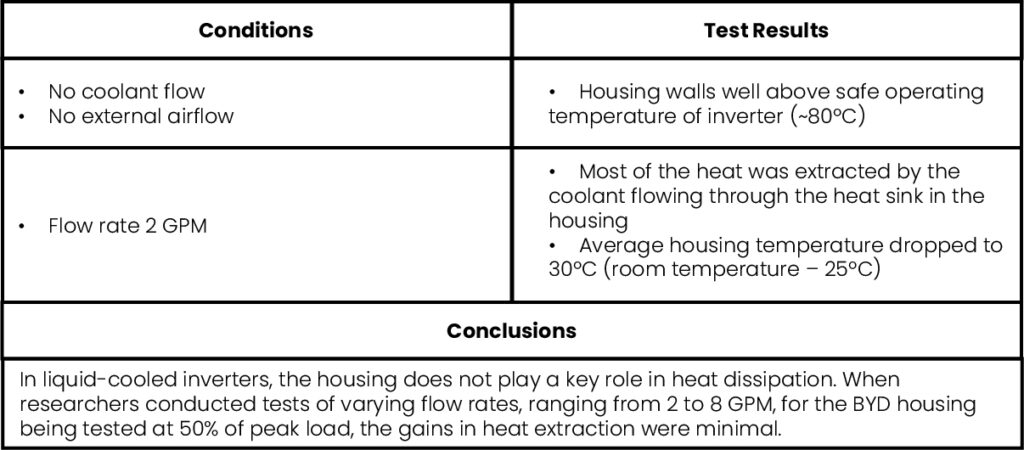

To test state-of-the-art inverter designs and the packaging approaches used to extract heat from power-dense inverter modules, the capstone student team at The Ohio State University constructed an experimental test rig.

When used with an inverter, the test rig emulates drive cycle electrical loading conditions and records the resulting housing temperatures, enabling the team to identify hot spots. The test rig was specifically designed to be interchangeable; that way it can test a variety of inverter housing specimens and designs.