6 Reasons Why Near-Sourcing is NOT a Sustainable Solution

A Special for Report Buyers, Planners, Sourcing Specialists, and Supply Chain Professionals

Executive Summary

NearSourcing is a strategy. Like any strategy, it’s not a one-size-fits-all solution. It has its pros. It has its cons.

So, if you think NearSourcing is a one-and-done strategy guaranteed to save you money, think again. Even in lean operations, few manufacturers take a close enough look at the real cost. Don’t make this mistake.

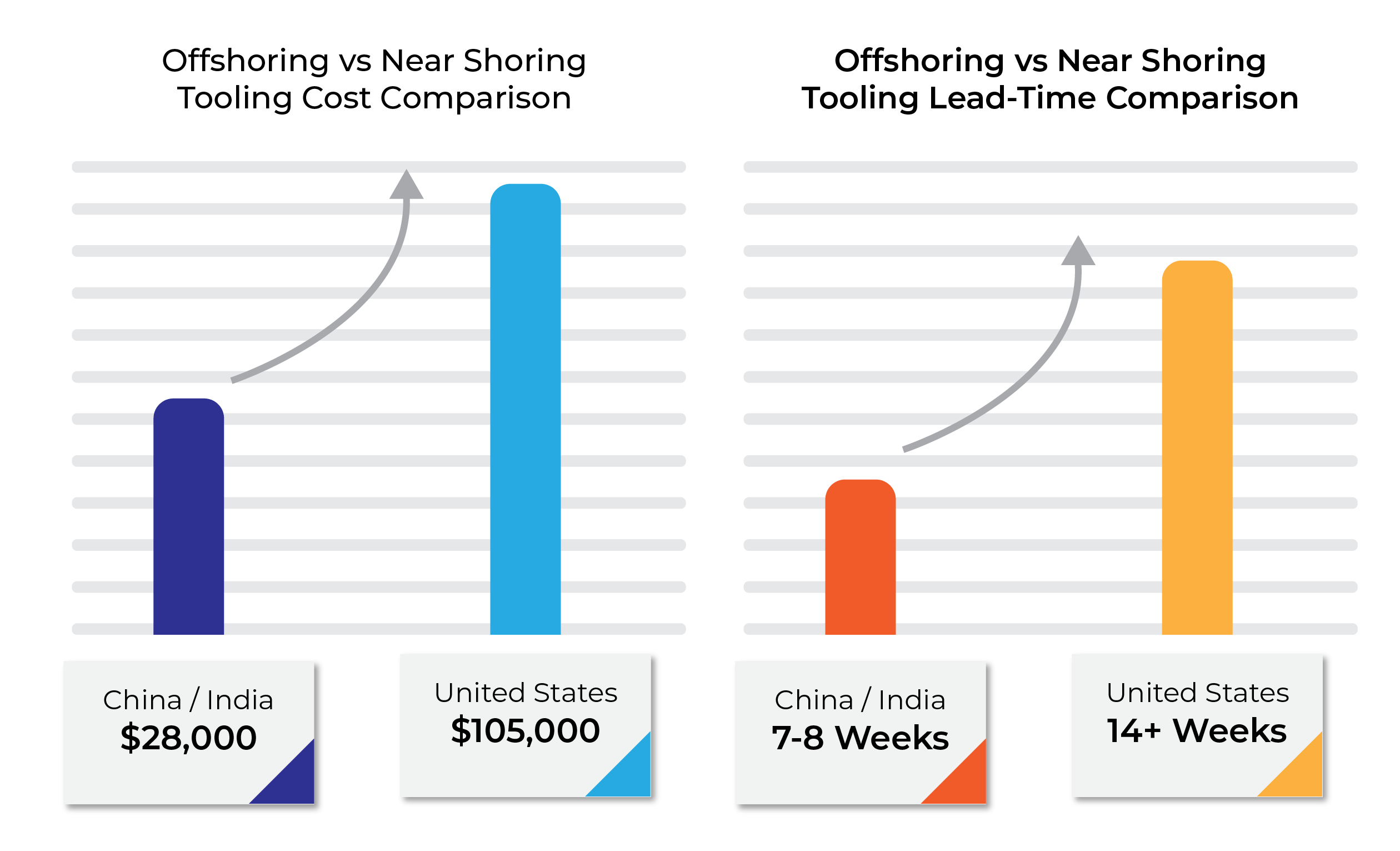

Any manufacturer looking only at initial cost savings is setting itself up to encounter some pitfalls. One such pitfall is not comparing total costs. For example, it’s fair to say that per-part costs go up as the number of production changeovers increases. These increases, however, are not identical across the board. NearSourcing parts in the U.S. goes up substantially over Global Sourcing the same parts in China or India. As an example, in a cost comparison of tooling development for an automotive manufacturer, a U.S.-based NearSourcing supplier yielded longer lead times and a 70% higher cost over the exact same development performed in China or India.

Still not convinced? Consider “hidden” or overlooked costs, such as labor. It’s also no secret that higher labor costs result in higher costs for the deliverable. It’s also no secret that labor costs vary widely among suppliers in the U.S., Mexico, and China. For this reason, offshoring can offer substantial cost savings. Let’s look at the automotive manufacturer again. U.S. labor is top-dollar. Mexico comes in second – but with labor 73% lower than the U.S.. Offshore suppliers come in even lower; 82% less than the U.S.

Which is why the key to deciding if NearSourcing is a viable strategy is to use actual facts and figures to play the strategy clear out to the end game. Then, and only then can you make sure you’ve made the right, cost-effective choice.

This special report is designed to walk you through a real-world example that shows what the true cost of NearSourcing can be. Based on the experience, observation, and analysis of a world-leader in supply chain, this report showcases six things you should know before choosing NearSourcing as your primary strategy.

Here are the six surprising things this white paper will cover:

- More (Costly) Production Changeovers

- Expensive and Time-Consuming Tooling Development

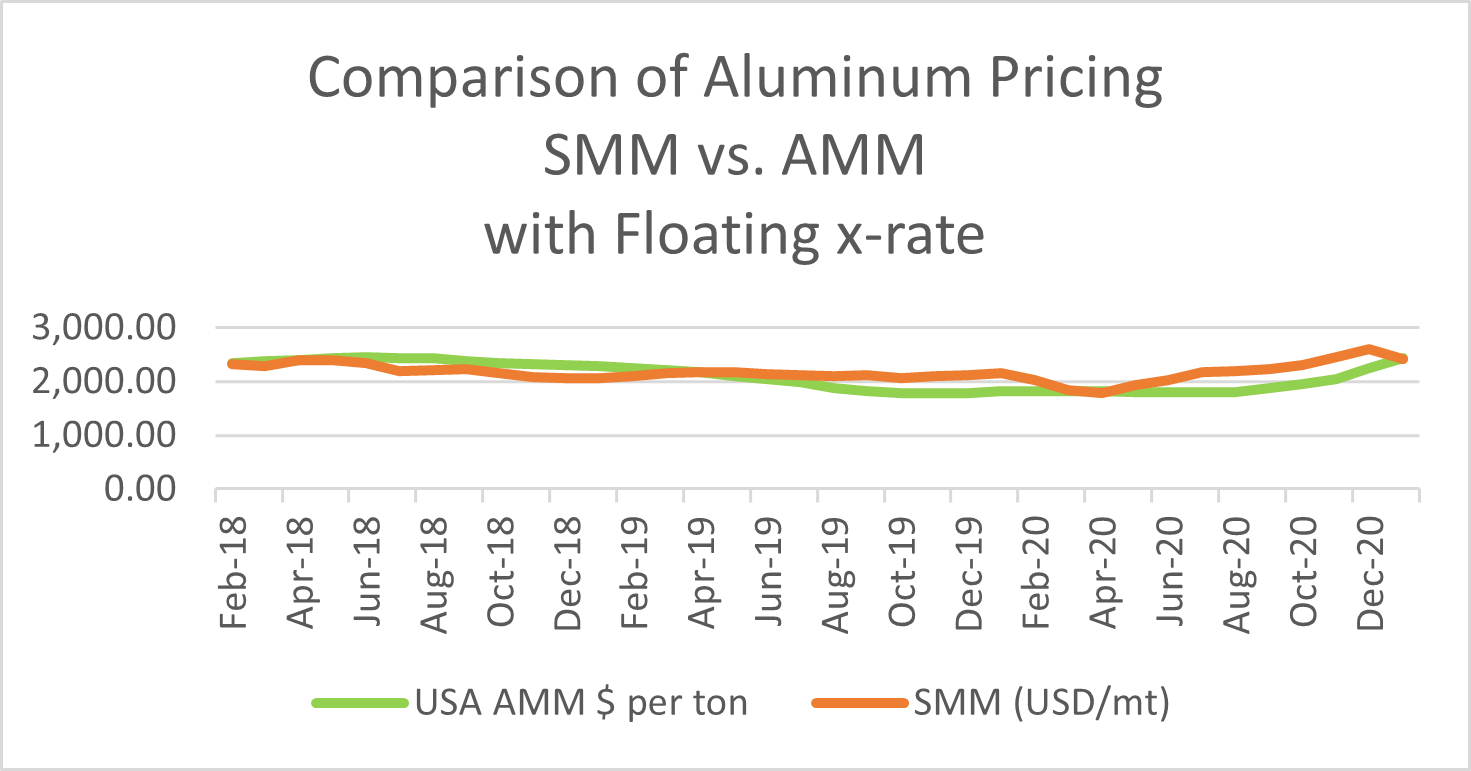

- Bigger Commodity Costs

- Higher Tool Set-Up Expenses

- Increased Trucking Rates

- Inability to Adequately Handle High Mix, Low Volume

Keep reading to find out what you don’t know about NearSourcing – and what it could be costing you.

Introduction

Every day, supply chain professionals are being asked to do more to support continuous improvement and leaner operations. Perhaps you’ve been asked or tasked with finding a solution to improve supplier performance. It’s possible you’ve searched for a magic lean supply chain solution that would bolster vendor communication, shorten lead times, and reduce costs. And maybe, just maybe, you thought you found it in a strategy known as NearSourcing.

What Is NearSourcing?

NearSourcing (Near-Sourcing or Near-Sourced) is a business strategy that involves establishing or moving some or all of your operations within proximity of where your end-product is sold. While not the polar opposite of Outsourcing – which means to procure goods and services from outside your organization, often from foreign or lower-labor-wage suppliers – NearSourcing is an alterative strategy.

In fact, there’s been great impetus for NearSourcing over the past several years. Manufacturers are increasingly using NearSourcing all types of products and commodities. And, in some instances, rightly so.

NearSourcing is absolutely the best solution for manufacturers to procure their needs. It reduces lead times, it’s easier to manage communications with domestic producers, and it’s easier to audit suppliers, as well as visit them for project and quality inspections.

Great! So, what’s the problem?

The Great Yet Unsustainable Solution

The problem is that NearSourcing is, frankly, impractical.

At the risk of offending some companies and buyers, we at MES, contend that NearSourcing is an unsustainable solution.

We don’t take lightly this bold statement. In fact, we back it up with observational study and statistical analysis rooted in our time-tested, proven solutions as a full-service provide of global manufacturing and supply chain management services.

Please hear us when we say that we’re all-in for domestic production close to customers. We’re also sold on preserving domestic jobs and the industrial economy.

And yet, we must look at the reality and practicality surrounding NearSourcing. The truth is, commercial challenges abound if your only strategy is NearSourcing.

How NearSourcing Costs More than You Think

To illustrate our point, we’ll crunch some numbers. But first, let’s assume something we all know to be true:

Today’s projects are far more complex than any project from even a few short years ago.

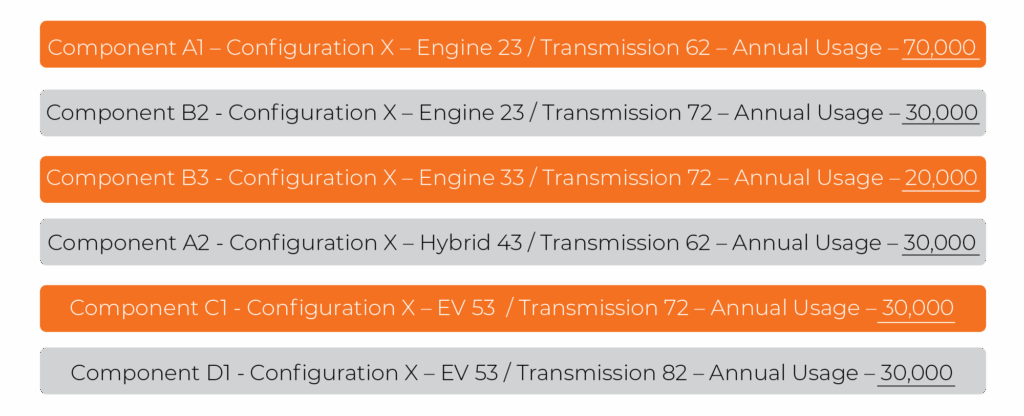

Take, for example, Monterrey Motors. It’s 2015 and this automotive manufacture has a mid-size SUV with 200,000 annual units. The options are pretty simple: two engines, two transmissions. Fast-forward to 2021 when both the world and Monterrey Motors have changed. Dramatically.

Today Monterrey Motors offers far more options in its lineup, including two engines, four transmissions, a hybrid, and a special electric vehicle model.

A chassis bracket used across all models looks like this: Please see chart below.