3 Signs – Optimize Your Supplier Relationship Management Process

Juggling suppliers is hard. There’s testing and quality control to contend with. There are lead times to factor in. And there are logistics routes, warehousing, and inventory management processes to streamline. Multiply each of these responsibilities times the dozens, hundreds, or even thousands of suppliers you’re working with and, well, it’s easy see why it supplier relationship management can be so tricky.

On top of that, your organization may be dealing with changes like acquisitions and mergers, plus all the things that go along with a change in your business, including new suppliers, cost negotiations, and purchasing order ins and outs.

With that much on the plate and on the line, it’s far too easy to keep the status quo – even if it’s costing you time and money. The good news is that you don’t have to.

We’ve got some answers to help you stop feeling overworked, overtaxed, and just “over” having to foster and maintain good supplier relationships.

Why Supplier Relationships Matter

Whether you’re an OEM, Tier 1 or Tier 2 supplier, you know that suppliers are your lifeline to successful production, order fulfillment, and, ultimately, happy consumers.

That’s why it’s essential to have good, solid, trustworthy relationships with your suppliers. Quality production, on-time delivery, and rapid troubleshooting can make all the difference between a supplier that adds value to your organization and one that doesn’t deserve your business.

A Good Supplier Is Not the Same as Good Supplier Management

But even a good supplier can leave you scratching your head (or tearing your hair out) over escalating costs, misaligned portfolios, post-merger upheaval, and shifts in consumer expectations and demands.

Sure, things can seem like they’re okay even when they’re not simply because you and your teams get used to operating in “crisis mode.” You may not even realize that you’re in a constant state of worry about extended lead times, not having native engineering support to ensure high-quality production, or the time wasted chasing parts on a global scale.

As good and reliable as a supplier might be, it’s impossible to tighten costs, quality, and delivery requirements with all that noise and chaos going on in the background. Unfortunately, that’s what having a good supplier without good supplier management can do: leave you and your teams feeling frantic and frenzied.

A Better Way …

Wouldn’t it be better if you could rely on someone else to deal with suppliers? Someone else to manage all the issues that come up with cost negotiations, capacity, inventory, and quality? That’s what one of our clients, a major manufacturer of electrical components like terminals and connectors, found out in working with MES.

Jose Deschamps, a sales/project manager for MES explains, “Our customer has their own sourcing team. The team already had secured a good, reliable supplier that was an expert in copper, their preferred material. Unfortunately, the supplier didn’t have a global presence, which meant they didn’t have the logistics in place for international shipping from India to the United States and Mexico. So, MES came in and did what we respectfully call a ‘takeover.’ That simply means is that we took on what may be called ‘the grunt work’ responsibilities: logistics, quality control, and product warehousing. Of course, this is what we do at MES. We’ve perfected the process so that rather than being a grind, we like to think of it as a kind of gift to our customers – something that frees them up to focus on more important strategic business objectives.”

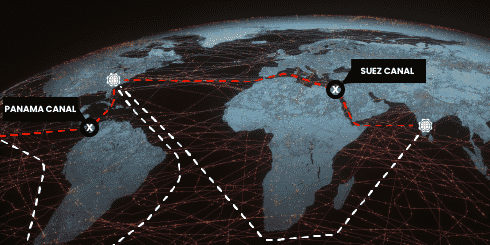

As part of the takeover process for this customer, MES worked to alleviate their immediately challenges; namely developing local and international logistics routes to shorten what long lead times from the supplier’s factory in India to the customer’s North American facilities.

The first order of business was having the customer send their drawings to MES for evaluation. Next, an MES team of engineers that live and work in India got busy conducting a full factory audit of the supplier, reviewing the quality control of samples, and ensuring that the products passed all the customers required quality and electrical tests. MES also built inventory in its warehouses according to the customer’s forecast, effectively reducing the lead time from more than two months to just two or three days.

“Before the MES takeover, our customer had to send a PO to the supplier, wait for the parts to be produced, then wait some more for them to get from India to North America. At a minimum, it took weeks and months,” says Jose. “Now, because we handle everything from forecasting to warehousing to just-in-time delivery, we’re able to deliver the parts to our customer in a matter of days and without any upfront capital costs on their part.”

3 Reasons Why You Need Supplier Consolidation

1.) It’s taxing your team, creating more challenges and fewer efficiencies

Imagine what your team could do with the time they currently waste making contact, issuing various agreements, and negotiating contract terms. Now imagine having experts take on those responsibilities and more, including in-person, at-the-factory product inspections anywhere in the world. This will save your teams countless hours testing and approving (or re-approving) products.

2.) It’s busting your budget big time.

With the MES takeover model, we’ll evaluate your unique situation and proactively seek cost-savings opportunities that allow you to continue working with your current suppliers. In return, you’ll receive better pricing, eliminate redundant tool cost investments, avoid MOQ setup costs, and reduce inventory expenses.

3.) It’s giving you unsatisfactory results.

Love your supplier but hate the hassles? We get it. Which is why the MES takeover model includes putting our elite engineers and quality experts on the ground wherever your supplier is located. Our teams will ensure that your supplier has the capacity to meet your requirements. The MES team will also align tooling quality and life, as well as streamline lead times, shipping routes, and warehouse locations to ensure the fastest delivery of the highest quality products.

Getting the Help You Need to Re-Engineer Your Process

Managing multiple suppliers all around the world isn’t easy. It takes a proverbial village to do it efficiently and cost effectively. Which is why you may want to explore how you, too, can surrender the headaches, hassles, and time spent managing your suppliers to the experts at MES.

Not only will we free up your time for bigger and better things, we’ll push your organization forward in terms of quality, lead time, and cost savings. Then, like our copper components electrical customer, all you’ll have to do is send your PO and receive your part in a matter of just a few days. Easy peasy.

Learn more here about the MES Supplier Consolidation Solution.