Developing Precision Machined Castings for Drivetrain Application

CUSTOMER SUCCESS STORY

When you’re a world leader in driveline systems and components, you expect world-class performance from your suppliers. So, when there’s a supplier quality issue and you’ve already employed reasonable and customary tactics to resolve it (to no avail), it’s time for drastic measures.

It’s time to find a new partner.

Here’s how MES stepped in to become this manufacturer’s reliable, go-to resource and exceed customer expectations and guarantee quality satisfaction.

Challenge: Lackluster Performance

One of the benefits of investment casting is the quality. Complex geometries are the norm and intricate designs are to be expected. The finished product can be likened to a very nice golf club that looks exquisite, has a fine surface finish, and showcases a remarkable level of detail.

As such, investment casting typically lands on the higher side of the expense line. There’s certainly nothing wrong with that, but only if the quality of the castings is impeccable. Unfortunately, for this manufacturer of power transmission solutions, that wasn’t the case.

“From a quality standpoint, they were tired of their investment caster in China,” explains Joe Scopelite, Senior Sales Account Manager at MES. “They were using a process that should have been delivering much higher quality parts. Even with their best try, their dropout rate was 20%. Frankly, what they were getting was essentially junk. Then, when the company tried to migrate away, the supplier fell apart.”

But that wasn’t the only challenge. In addition to being too time-consuming and expensive to manage a lackluster overseas supplier, this manufacturer, which serves a variety of industries including construction and agriculture, found it too costly to handle the physical inventory themselves.

Insights: Find an Alternative

There’s more than one way to skin a cat, as they say. There’s also more than one way to cast parts. In working with our new customer, we recognized several things about their struggle, including:

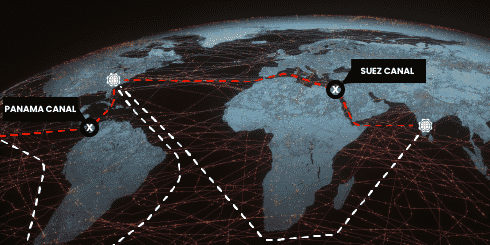

- The global business environment for import castings is extremely turbulent and only getting worse.

- It was extremely difficult for them to find suppliers willing to guarantee quality while also developing a mutually beneficial business relationship.

- It wasn’t feasible for them to have a local presence at the factory to collaborate and resolve quality or other manufacturing issues.

- The primary issue was quality, not the type of casting.

This told us two things: (1) They would benefit from MES’s best-in-class supply chain solutions and value-added services; and (2) they were open to exploring an alternative casting option, as long as it met their exacting quality expectations.

And, if we were able to help them realize a cost savings, so much the better.

Solution: Global Reach

Our business model includes providing a strong support resource to deal with the supply chain pitfalls associated with global sourcing. So, the first thing we did was migrate our new customer away from their sub-par investment casting supplier and toward our quality-first sandcasting supplier.

Through our global network, we sourced a quality-committed supplier in India. By switching from investment casting to sandcasting, we’re delivering a higher quality part than the supplier in China and doing so even faster.

For this customer’s parts, there are critical geometric tolerances that can only be checked with a coordinate measuring machine or CMM. Although our foundry supplier does not have a CMM to perform the necessary checks, we’ve taken ownership and are checking these features with our own CMM so that we can ensure we’re satisfying the critical demand that the company’s engineering and quality control people expect (and rightly so).

MES also has conformed with our customer’s radiographic and magniflux tests to ensure that our supplier’s casting processes always deliver the required quality. In fact, because MES is so committed to ensuring quality, there’s isn’t a test criterion they’ve thrown at us that we haven’t embraced and incorporated into the pre-production part prove-out process.

As a result of this diligence and commitment, this solution is on track to yield a nearly $500,000 savings for our customer in the first year – and we’re not even in full production yet on a total of 33 parts.

We also have relieved them of their inventory woes by keeping and managing an inventory of their parts in our Ohio warehouse. By drawing from our parts cache rather than overseeing the supply chain pipeline themselves, our customer have saved countless amounts of time, money, and hassle.

Results: Approved and Appreciated

“MES has a strong, collaborative team that’s committed to addressing our customer’s needs,” says Joe. “Our customers has expressed their appreciation and approval for our team’s work in providing superior quality castings, on time, at competitive prices, while easing the burden of having to manage their day-to-day supply chain issues. MES has proven to be a great fit, yet we’re not stopping where we are. MES continues to generate key new supply chain resources through innovative business ventures and service programs, offering our customer even more value.”

Ready to explore alternative solutions that may save you thousands? Contact MES to learn more.